Next Topic

Select SDGs to find out how we are taking action in support of the UN Substinable Development Goals

2021 ISRAEL CHEMICALS LTD. | ALL RIGHTS RESERVED

ICL’s Food Specialties business brings over 75 years of experience to the food industry. Its diverse product portfolio consists of high-quality functional phosphate and mineral systems to deliver buffering, pH adjustment, protein protection and shelf life enhancement across multiple markets, including Meat, Poultry, Seafood, Dairy, Beverage, Bakery, and Alternative Proteins. Read more on ICL’s food related solutions.

The ICL Food Specialties Team continues to expand its reach by recognizing the growing market for alternative proteins. ICL’s innovative technology enables the production of meat substitute products that are welcome alternatives to conventional meat products for flexitarians and health-conscious consumers who wish to reduce their meat consumption without compromising taste or texture.

ICL’s innovative processing technology enables the production of meat substitute products.

ICL has developed proprietary technology, enabling the manufacturing of vegetable-based proteins that are virtually indistinguishable from traditional meat products. Using standard food processing equipment, ICL’s dedicated scientists found ways to create a wide range of tailor-made products including burgers, nuggets, fish fingers, meatballs and sausages, among others. This portfolio, known as the ROVITARIS® System, transforms proteins that give fibrous textures, as well as texturates and emulsions. The versatility of these different forms allows for highly-adaptable texture, color and taste as well as the possibility to produce vegetarian, vegan, and allergen-free solutions.

ICL Food Specialties has won numerous awards for this technology, including the 2019 FI Innovation Award: Protein Category in Paris, France, and the 2018 FiSA tradeshow “Most Innovative Ingredient” award in South America.

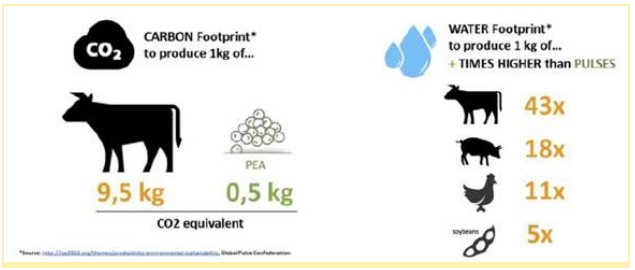

Along with growing challenges to our environment and climate, public awareness and concern is increasing. Many consumers are lessening their ecological footprint by reducing meat consumption and switching to meatless alternatives. Plant-based protein sources consume less water and produce less CO2 compared to the production of conventional animal protein, making them a more sustainable and less environmentally impactful food choice.

ICL decided to invest $18M to develop new capabilities dedicated to manufacturing plant-based fibrous products.

ICL decided to invest $18M in a new manufacturing facility that will produce plant-based fibrous products. Located at ICL’s Carondelet site in St. Louis, Missouri, the new plant will allow the Company to increase production capacity of its ROVITARIS® line, which will help to drive innovation and production in the alternative protein market.

Processed Cheese Storage, “outside the fridge” with a guaranteed long shelf life. All spreadable processed cheese, made with ICL’s JOHA product range, can be stored outside the fridge, saving energy.

The exceptional shelf life (up to 2 years) permitted by the sterilization process and the use of JOHA salt, reduces food waste. This is highly relevant for emerging countries in which a closed cooling chain for food is not guaranteed. This also increases food safety. The longer shelf life makes dairy protein more accessible for a broader population.

Each day, more than 1% of the production of an average cheese factory cannot be used in end products and delivered to customers. This is caused by:

ICL’s solution limits losses in the cheese curd molding stage. Small pieces outside of the mold (0.5% of the total cheese mass) are normally lost. ICL’s production process reuses this otherwise wasted raw material to produce processed cheese. This process permits retaining the high protein value of the cheese for human consumption. The accumulated material savings reduces both process waste and unnecessary pollution throughout the supply chain (as less raw material needs to be consumed).

By 2030, end hunger and ensure access by all people, in particular the poor and people in vulnerable situations, including infants, to safe, nutritious and sufficient food all year round.

By 2030, ensure sustainable food production systems and implement resilient agricultural practices that increase productivity and production, that help maintain ecosystems, that strengthen capacity for adaptation to climate change, extreme weather, drought, flooding and other disasters and that progressively improve land and soil quality.

By 2030, halve per capita global food waste at the retail and consumer levels and reduce food losses along production and supply chains, including post-harvest losses